INSPECTION SERVICES

Tube Inspection

Tube Inspection is to check tubes to detect anomalies such as corrosion and manufacturing defects. Tubing can be found in such equipment as boilers and heat exchangers. In Danamin we have RFET, ECT, IRIS & MFL for Tube Inspection package.

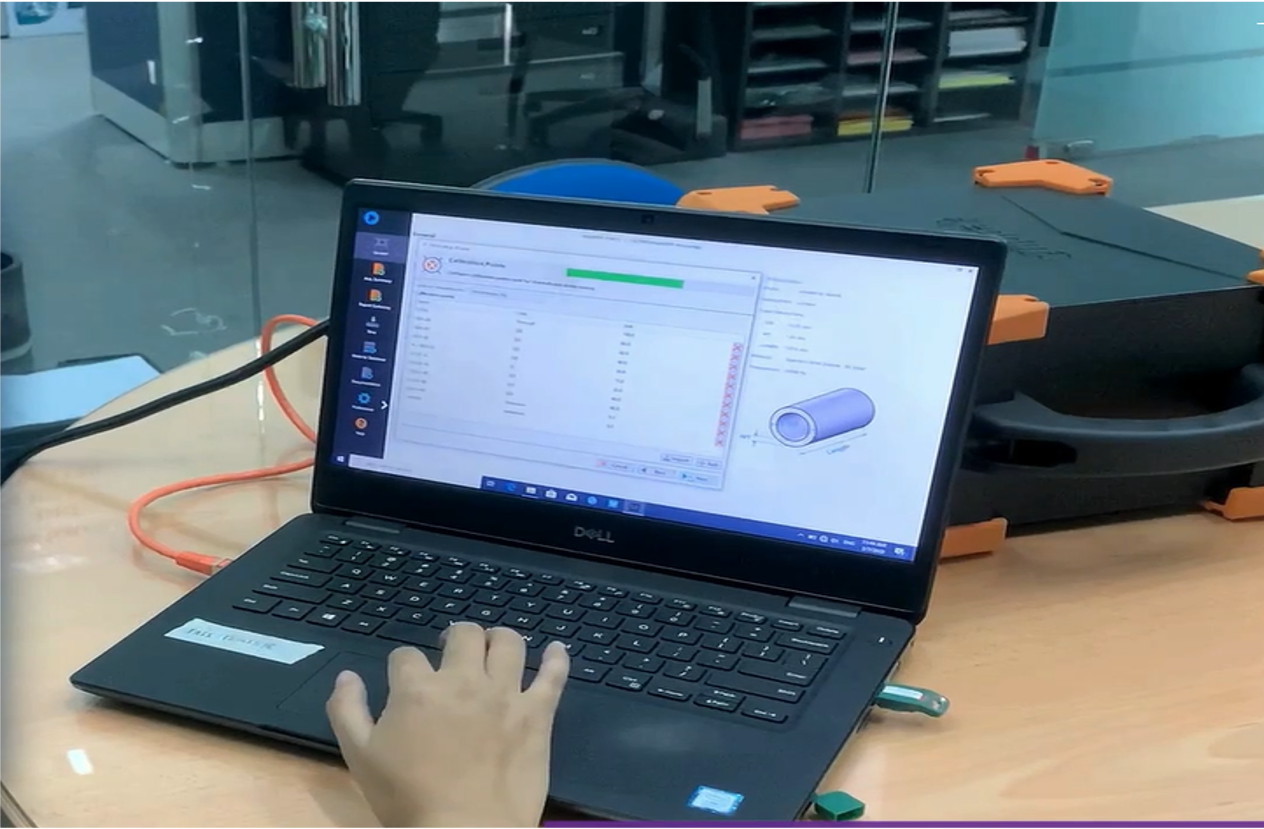

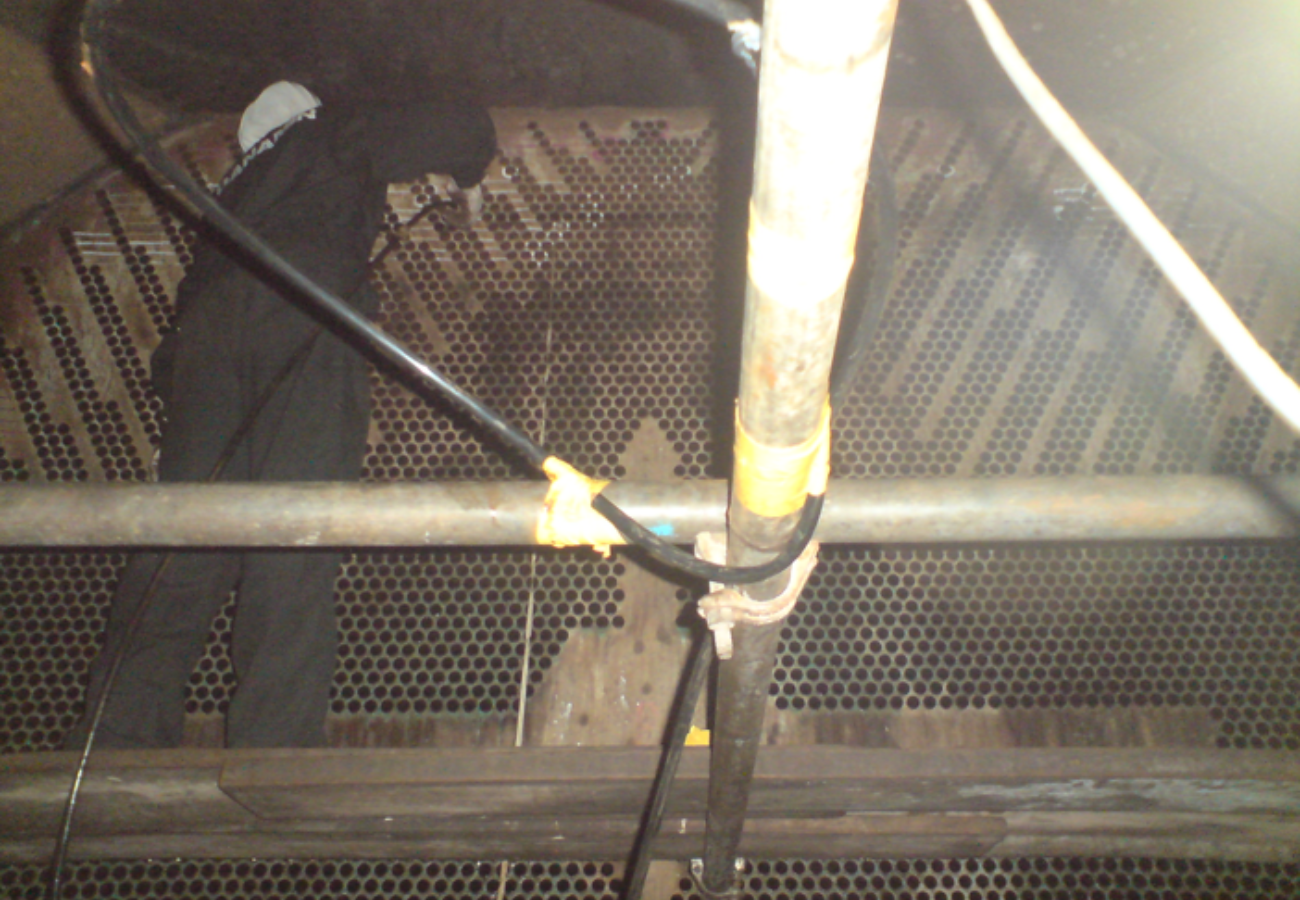

Internal Rotating Inspection System (IRIS)

Internal Rotary Inspection System (IRIS) is used to detect corrosion, pitting and wall loss and is most commonly used for tube inspection in boilers, heat exchangers, air coolers and feed water heaters & suitable for ferrous & non-ferrous materials, and also can be used on a wide range of tube diameters and wall thicknesses.

CRT is suitable for:

- Accurate wall thickness measurements

- Both internal & external defects detection

- To locate position along tube length

- 100% coverage of the tube

- As a back-up to RFET, MFL & ECT

Eddy Current Testing (ECT)

Eddy Current Testing (ECT) makes use of electromagnetic induction to detect and characterize surface and sub-surface flaws in conductive materials by using a coil of conductive wire is excited with an AC current to produces an alternating magnetic field around itself.

- ECT applicable to detect surface & near-surface defects

- The test probe does not need to make direct contact with the test part

- ECT can be used for more than flaw detection

- ECT require minimal part preparation

Magnetic Flux Leakage (MFL) – Tube Inspection

MFL Tube Inspection used strong permanent magnets to magnetize conductive tubes. Magnetic field is induced into the tube material which forms a magnetic circuit between the part and the probe to detect pitting, circumferential cracks, and wall losses in ferromagnetic tubes such carbon steel, nickel, and ferrous stainless steel.

MFL Advantages:

- Detect axial, radial & circumferential discontinuities

- High sensitivity for pitting & circumferential cracks

- Not affected by the presence of aluminium fins

- High speed inspection technique

MFL can be used for:

- Aluminium finned tubes

- Ferromagnetic heat exchanger tubes

- Checking internal and external discontinuities