INSPECTION SERVICES

Advance NDT

Advanced NDT offers an unmatched capability of applications ranging from weld inspections to the detection of hidden cracks, voids, porosity and other internal irregularities in metals and composites. Our personnel are certified by AELB, ASNT, CSWIP, PCN & API.

Computed Radiographic Testing (CRT)

Computed Radiographic Testing (CRT) is the digital Rt that shortened the time to produce an image. Instead of physical film imaging oriented, CRT image produced in digital imaging format.

The digital image is then displayed on a computer monitor for evaluation with special software.

CRT can be used in:

- Aerospace industries

- Automotive industries

- Manufacturing industries

- Marine industries

- Military defence

- Offshore industries

- Petrochem industries

- Power-gen industries

- Transport industries

Phased Array Ultrasonic Testing (PAUT)

Phased Array Ultrasonic (PAUT) used multiple elements to steer, focus & scan beams with a single transducer assembly. The ability to test ferrous & non-ferrous welds with multiple angles from a single probes can increase the probability to detect animalities precisely.

PAUT can be used in:

- Oil & gas

- Petrochemical

- Power generation

- Steel structure

- Pipeline

- Manufacturing

Borescope/Fiberscope/ Videoscope

Borescope/Fiberscope/Videoscope are used for visual inspection work where the area to be inspected is inaccessible by other means for recognizing defects or imperfections.

Borescopes commonly used in:

- Manufacturing

- Aviation

- Industrial gas turbines

- Engines

- Tubes

- Small opening areas

B-Scan (Corrosion Mapping)

B-Scan refers to the 2-D image produced when the data collected from an ultrasonic inspection is plotted on a cross-sectional view of the component, depicting material thickness measured at different positions over time.

B-Scans can be used in:

- Oil & gas

- Automotive industries

- Manufacturing industries

- Marine industries

- Military defence

- Offshore industries

- Petrochem industries

- Power-gen industries

- Transport industries

C/B-Scan : Corrosion Mapping

C/B-Scan provide precise thickness measurement of wall thickness & a virtual picture of the damage or corrosion spot or area through repeatable images displaying in top view (C-Scan) & sectional view (B-Scan).

C/B Scan can be used to inspect ferrous & non-ferrous material.

C/B-Scan can be used in:

- Oil & gas

- Automotive industries

- Manufacturing industries

- Marine industries

- Military defence

- Offshore industries

- Petrochem industries

- Power-gen industries

- Transport industries

Indoor & Outdoor Drone

Drone is a new approach to perform certain NDT and inspection activities with safer, cost efficient and time saving options. Drone offers both indoor & outdoor activities for surveillance, visual inspection, gas detection & ultrasonic testing.

Drone can be used in:

- Oil & gas

- Petrochemical

- Power generation

- Large scale solar farm

- Palm oil plantation

Thermographic Infrared (IR)

Thermographic Infrared technique is a temperature measurement technique that visualizes the thermal energy emitted by the identified object surface.

Thermal images taken of the object surface are then constructed from electromagnetic wavelengths in the long-wave infrared spectrum range from 0.9 μm to 14 μm. (Shortwave & Longwave).

IR is applicable for:

- Boiler

- Furnace

- Chimney

- Flare tower

- Heat exchanger

- Rotating machineries

- Pipeline

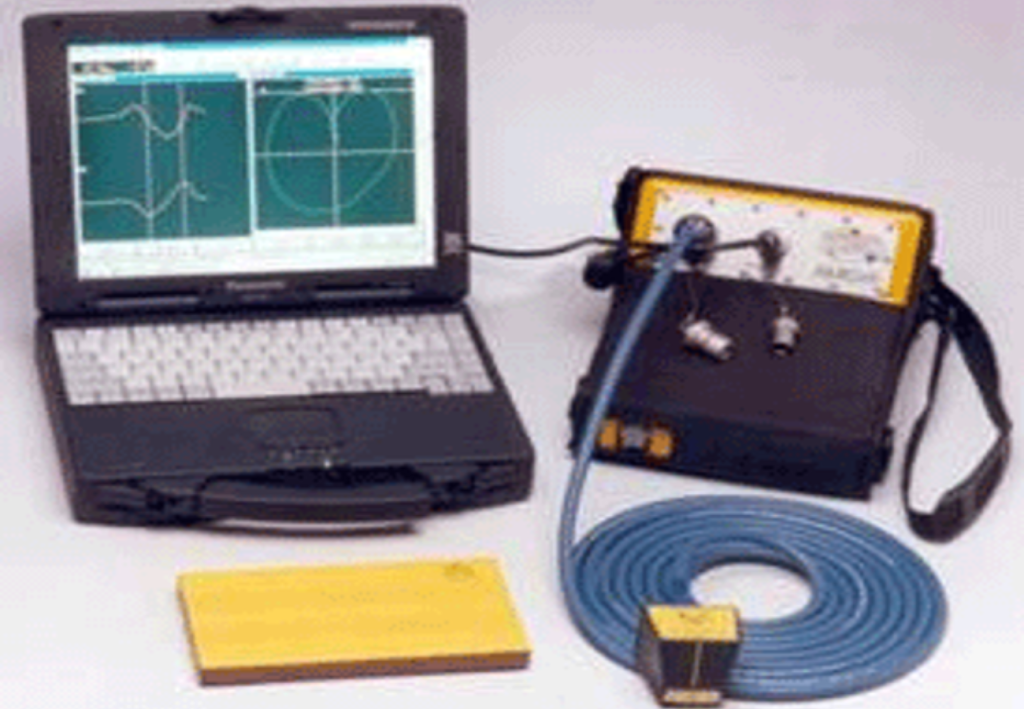

Electro Magnetic Acoustic Transducer (EMAT)

Electro Magnetic Acoustic Transducer (EMAT) is non-contact UT technique that generates ultrasonic waves into a test object using electromagnetic induction with two interacting magnetic fields.

EMAT is applicable for:

- Inspection of in service piping

- Inspection of tubular

- Inspection of wall thickness pipe at support

- Inspection of vessel

EMAT can be used in:

- Construction

- Oil & gas

- Petrochemical

- Marine

- Military

- Logistics

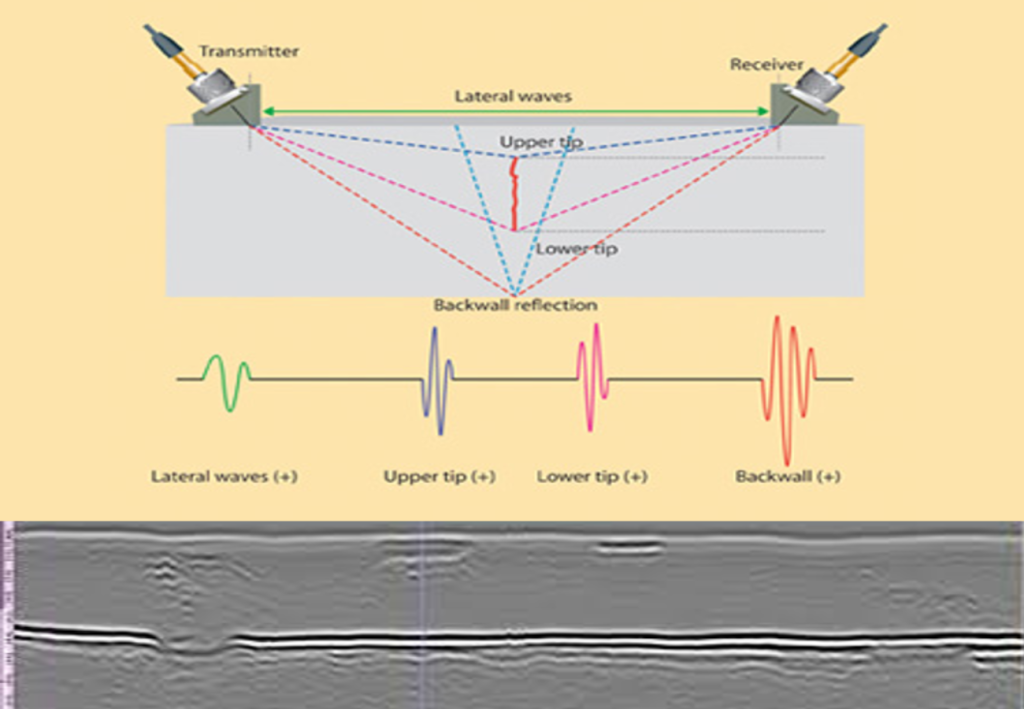

Time of Flight Diffraction (TOFD)

Time of Flight Diffraction (TOFD) is a high speed weld inspection that can locate and measure different types of defects precisely with incredible cross sectional view (D-Scan) of the tested material in a real time imaging system.

TOFD able to detect damage which would traditionally only be able to be detected through other techniques, such as pulse echo or RT.

TOFD can be used in:

- Oil & Gas

- Petrochemical

- Power generation

- Steel structure

- Pipeline

- Manufacturing

MFL Floor Scanning

MFL Floor Scanning is using magnetic field to detect corrosion and pitting in carbon steel.

A powerful magnet is scanned close to the surface to ‘saturate’ the steel with the magnetic field. The magnetic field “leaks” is then detected as corrosion.

Advantages:

- Faster to cover large areas

- Minimal set-up time

- Qualitative assessments result

- High sensitivity: up to 0.500” thickness

- Only require one side of the material

Alternating Current Field Measurement (ACFM)

Alternating Current Field Measurement is an electromagnetic technique used to detect & sizing of surface breaking cracks in metallic components and welds.

ACFM also can measure crack underneath paint/coating with little or no surface preparation needed.

ACFM can be used for:

- Detect & sizing of cracks & corrosion

- Inspection of fillet welds for drilling units

- Inspection of fillet welds at bridges

- Railways & aviation components

- Pressure vessels, storage tanks & piping

- Inspection of drilling tools

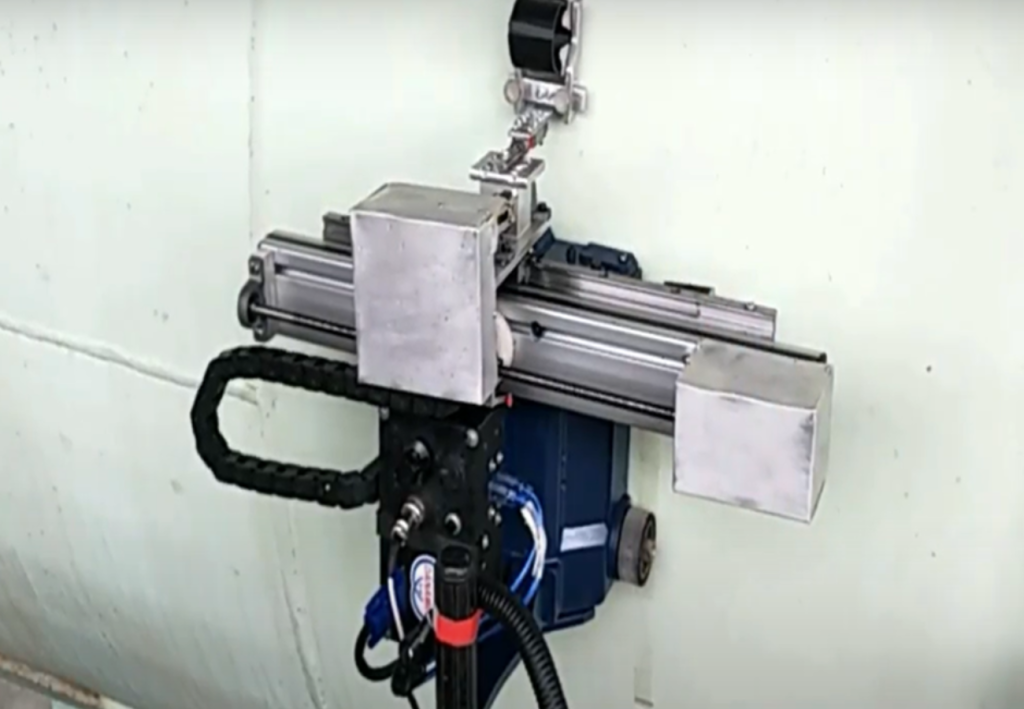

Ultrasonic Testing Crawler

UT Crawler used to conduct a remote control ultrasonic testing on above ground ferro-magnetic structures without the need of costly scaffolding or rope access.

UT Crawler is capable to produce B-Scan thickness image which can be saved for future reference.

UT Crawler can be used in:

- Oil & gas

- Petrochemical

- Storage tank farm

- Construction

- Oleochemical

- Shipbuilding & ship repair